With one of the largest portfolios of polymer and engineered materials solutions and its leading experts in the industry, Celanese can help you make your next idea a reality.

Its performance-driven engineered plastics & materials are designed to help you meet critical requirements, including lightweighting, dimensional stability, impact resistance, low friction and wear, and low moisture absorption. Celanese material solutions can also help reduce system costs, help meet environmental goals, and improve safety compliance.

While Celanese is headquartered in Dallas, Texas, it has a global network of commercial offices, technical centers, 27 production facilities, and additional strategic affiliate production facilities.

Celanex®

PBT

Polybutylene Terephthalate

-

Hard, Rigid and Strong

-

Continuous Use Temperature

to 140°C -

High Dimensional Stability

-

Good Chemical & Stain Resistance

-

Excellent Surface Properties & Appearance

-

Rapid Crystallization & Fast Cycle Time

Celstran®

LFT

Long and Continuous Fiber Reinforced Thermoplastic

-

Very Good Melt Flowability

-

Very High Impact Resistance

-

Low Warpage

-

Superior Chemical & Corrosion Resistance

-

Low Emission Grades

-

Eco-Friendly Processing; Recyclability

Fortron®

PPS

Polyphenylene

Sulfide

-

Service Temperatures up to 240°C

-

Very Good Resistance to Chemicals and Solvents

-

Inherent Flame Resistant

(UL 94 V-0, some grades 5VA) -

Very Low Moisture Absorption

-

Suitable for Lead-Free Soldering

-

Excellent Creep Resistance Even at Elevated Temperatures

Santoprene® TPV

(Medical Only)

Thermoplastic Vulcanizates

-

Outperforms Other TPEs in terms of Long Term Compression Set and Chemical Resistance

-

Medical Standards Compliance:

Biocompatibility Testing

ISO 10993-10US Pharmacopeia (USP)

Class VI -

Drug Master Files maintained with FDA

Rynite®

PET

Polyethylene Terephthalate

-

Very Hard, Rigid and Strong

-

High Heat-Distortion Temperature (HDT/A to 228°C)

-

Service Temperature to 150°C

-

Good Low Friction and Wear-Resistant Properties

-

Very Good Electrical & Dielectric Properties

-

High Chemical Resistance & Weathering Resistance

Zytel®

PA

PA 6, PA 66, PA 612

PA66/6 Copolymer,

PA 66/6T Copolymer

-

High Mechanical Strength

-

Excellent Balance of Stiffness & Toughness

-

Good High Temperature Performance

-

Good Electrical & Flammability Properties

-

Good Abrasion & Chemical Resistance

-

Available in Modified & Reinforced Grades

Celanese delivers cost-effective solutions to address automated and electric vehicle challenges including range, energy efficiency, thermal management, and safety enabling the development of safer, lighter, and energy-efficient vehicles for a more sustainable future.

Related Resources

Looking for more information on a specific industry or application? The content below provides information that can help customers learn about the products and services that Formerra offers in areas such as Transportation, Healthcare, Packaging, Industrial applications and more.

Celanese Solution Showcase

Flexible TPV for Peristaltic Pump Tubing

Santoprene® thermoplastic vulcanizates (TPV) offer outstanding flex-fatigue resistance, producing highly elastic peristaltic pump tubing that resists kinks, retains its shape and is compatible with barbed fittings.

Able to withstand a high number of flex cycles with minimal compression/tension set or loss of weight due to abrasion, Santoprene® TPV helps deliver tubing that lasts, and extends the service life of peristaltic pumps.

Formerra Automotive

Supplier Line Card

OEM, Tier Supplier or Molder - at any point in the automotive process, we have resources and capabilities available to help you from design realization to mass production.

Formerra Healthcare

Supplier Line Card

As new healthcare innovations enter the market, our 30+ years of material expertise and regulatory experience can help get your medical device to market safely and efficiently.

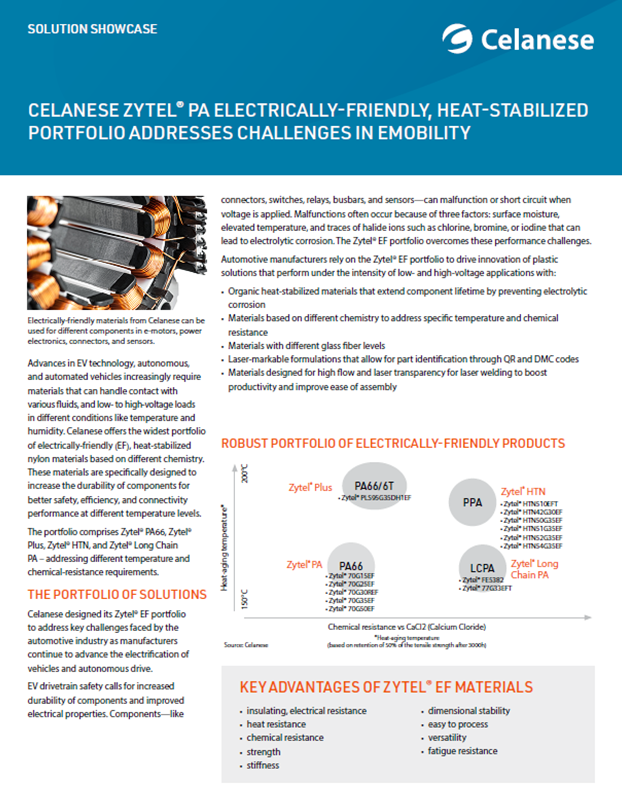

Celanese Solution Showcase - eMobility

Zytel® PA electrically-friendly, heat-stabalized portfolio addresses challenges in eMobility.

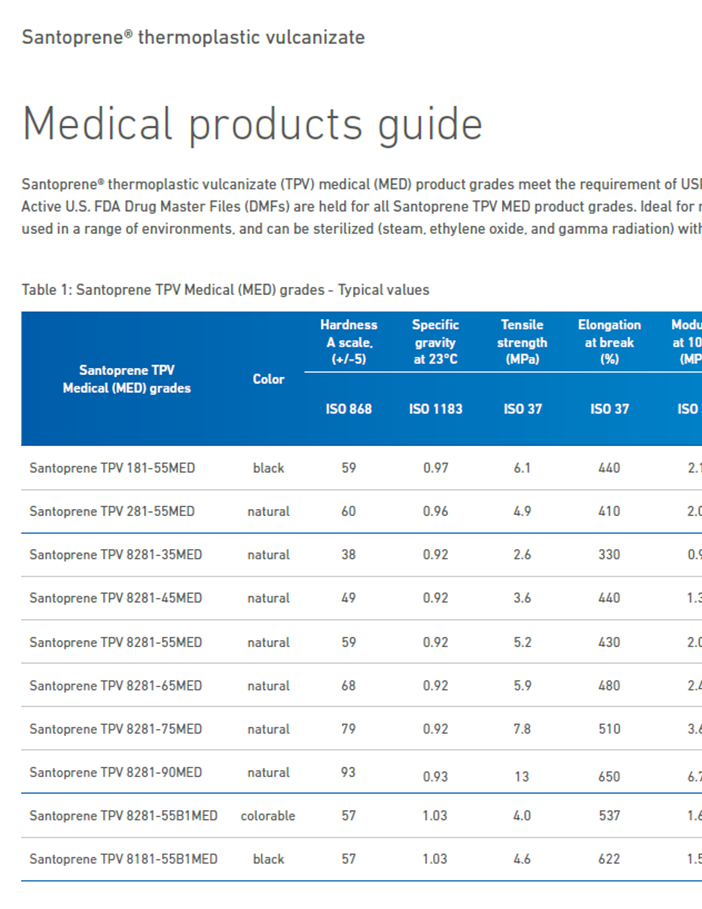

Santoprene® TPV (Medical) -

Medical Products Guide

Santoprene® TPV medical product grades meet the requirement of USP Class VI and ISO 10993-1 Biocompatibility.

Materials

Amcel®

POM

Amcel® acetal copolymer is a low or medium-viscosity, general purpose injection moldable grade.

Ateva®

EVA

Ateva® EVA polymers are high-performance ethylene vinyl acetate copolymers containing up to 42% vinyl acetate content.

Ateva® G Medical EVA

Ateva® EVA polymers are high-performance ethylene vinyl acetate copolymers containing up to 42% vinyl acetate content.

Celanex®

PBT

Celanex® PBT is a semi-crystalline polyester with a very high dimensional stability and is quite hard and rigid in nature.

Celanyl®

PA

Celanyl® PA nylon compounds can address multiple thermal, mechanical, electrical and tribological requirements.

Celcon®

POM

Celcon® acetal copolymer is a linear structure with a highly crystalline quality providing a variety of characteristics.

Celstran® LFT

Celstran® long fiber thermoplastics unite long fiber reinforcements with advanced thermoplastic resin.

CoolPoly®

PA

CoolPoly® is a lightweight, thermally conductive polyamide allowing greater design freedom in multiple applications.

Crastin®

PBT

Crastin® PBT is a semi-crystalline polyester with high dimensional stability and is quite hard and rigid in nature.

Ecomid®

PA

Ecomid® PA is a nylon synthetic polymer composed of polyamides and can be mixed with a variety of additives.

Fortron®

PPS

Fortron® is a high-temperature thermoplastic that offers excellent thermal, mechanical and chemical resistance.

Frianyl®

PA

Frianyl® flame retardant nylon PA compounds meet stringent industry requirements with multiple grades UL Listed.

GUR®

UHMW-PE

GUR® UHMW-PE offers outstanding abrasion resistance, impact resistance, non-sticking and self-lubricating properties.

Hostaform®

POM

Hostaform® polyoxymethylene copolymer provides a higher stability to thermal and oxidative degradation.

Hytrel®

TPC-ET

Hytrel® is a high-temperature, high-performance copolyester with good resistance to chemicals and heat.

Kepital®

POM

Kepital® POM provides enhanced tensile strength, improved impact resistance, and increased stiffness.

OMNIPRO®

PP

OMNIPRO® polypropylene formulations are ideal for pump housings, wheels, handles, mounting brackets, and levers.

Polifor®

PP

Polifor® polypropylene features easy processability and the ability to be modified through a range of reinforcing agents.

Rynite®

PET

Rynite® PET provides superior thermal and chemical resistance with the ability to support higher temperature exposure.

TPV (Medical Only)

Santoprene® TPV is proven to outperform other TPEs in terms of long term compression set and chemical resistance.

Talcoprene®

PP

Talcoprene® PP are polypropylene-based homopolymers or copolymers filled with talc.

Thermx®

PCT

Thermx® PCT is a high-temperature polyester based on polycyclohexylene-dimethylene terephthalate chemistry.

Vandar®

PBT

Vandar® offers outstanding ductility and stiffness, combined with excellent chemical and environmental resistance.

Vectra®

LCP

Vectra® delivers exceptionally precise and stable dimensions, high-temperature performance and chemical resistance.

Zenite®

LCP

Zenite® is a halogen-free, high-performance polymer providing high-temperature performance in eco-friendly applications.

Zytel®

PA

Zytel® polyamide resins deliver high-performance benefits ranging from stiffness to heat resistance.

We're here to help and answer any questions you may have.

Customer Service & General Inquiries:

- Phone: 1.888.502.0951

- Email: inquiries@formerra.com

Technical Support Hotline:

- Phone: 1.866.765.9824

- Email: phd@formerra.com

.png)